QUALITY CONTROL

We test to your requirement

We can tailor to your specifications. We cater for various quality controls

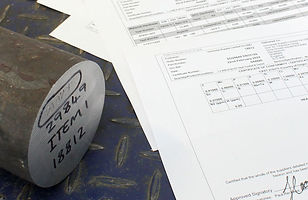

Material Specification

Where required the material we source comes with full certification to the material specification that was ordered. This gives us and the client full traceability on the products we produce on their behalf that are up to the correct specification.

Dimensions

We have various instruments to check all measurements when required on the parts we manufacture and purchase. We know the importance of dimensions and how they are critical in the industries we supply. If requested, we are able to provide a dimensional report with the release documents.

Hard Test

Testing the materials hardness is crucial on some of the parts we provide so we have the industry leading machines to make sure all components that go out are up to the correct specification the client ordered.

Country of Origin

We know how important traceability is in the manufacturing process so if required any issues can be located and resolved quickly. All documentation is made a top priority in the process of supply chain purchasing.

Coating Certificates

We provide full certification for processes used in the coating process. We know it is important to have full accountability when trying to resolve any issues later in the products life cycle.

Load Test Reports

We can acquire load testing reports for any of the items supplied when required. This is an extra process that comes as an additional request.

COC

Certificate of Conformance

When required we provide certificates of conformance for the required items. All documentation will come as a digital PDF format. This is an extra process that comes as an additional request.

PMI

Positive Material Identities

When required we can provide proved a PMI certificate in the release documentation. All documentation will come as a digital PDF format. This is an extra process that comes as an additional request.

NDE

Non Destruction Examination

When required we can provide NDE certification in the release documentation. All documentation will come as a digital PDF format. This is an extra process that comes as an additional request.

Etching

Etching is a process to apply batch numbers and codes to parts, or other information that may be required. This is a great way to follow up on traceability further down the line of the parts life cycle. If there is any specific information which is required to be marked on the parts, please inform us at the enquiry/order stage.

Wax Protection

Our heated wax protects the parts most vulnerable sections. This protection is great for shipping and storage and easy to remove by peeling away.